Production

Product Flow Chart

Casting Process

| Step 1. Investment Casting Engineering Team - Cast-Friendly Design | |

| LIN CHIAO's 24-years of alloy casting experience allow them to come up with innovative solutions to provide an accurate and versatile investment casting process. |  |

| Step 2. Wax Pattern / Wax Injection Condition, Time and Stability | |

| When injecting wax into the mold, the wax pouring pressure (7~12kg/cm2 or 50 kg/cm2), pre-heat mold temperature, wax injection time and temperature, wax pattern injection room temperature and the mold cooling method after wax is injected are the important factors for the wax injection process. Water Soluble was is also applied during casting process. |  |

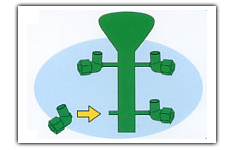

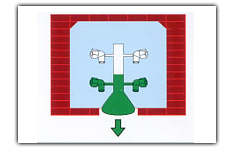

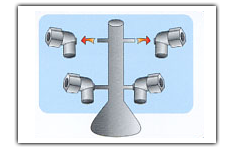

| Step 3. Wax Pattern Assembly | |

| Wax pattern is removed from the mold, staff would remove the burrs on the wax pattern and make sure the surface is clear. |  |

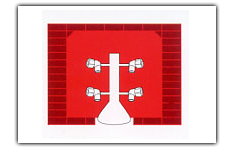

| Step 4. Shell Making of Investment Casting Process - Dipping | |

| Ceramic shell is a combination of ceramic slurry, which contains colloidal silica, alumina, stucco, etc. The tree is dipped in the ceramic slurry for the suitable thickness. |  |

| Step 5. Sand Coating | |

| Sand coating takes about three days to finish the whole process between the drying time and procedures. |  |

| Step 6. Dewaxing | |

| Was is removed after the coating is done. |  |

| Step 7. Shell Mold Firing | |

| Investment casting molds are fired in an oven at 1800 degrees Fahrenheit using steam to remove any volatiles. |  |

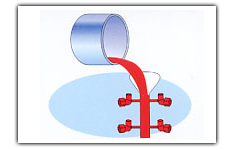

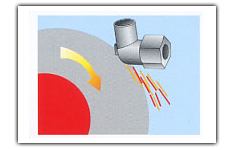

| Step 8. Molten Metal Pouring | |

| The liquid metal is poured in an investment casting shell; time and temperature are important factors for this step. |  |

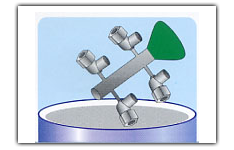

| Step 9. Shell Removal | |

| Shell Knockout Using Shaking Machine |  |

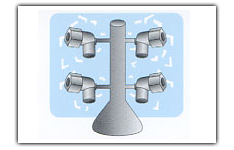

| Step 10. Tree Removal | |

| Individual casting product is removed from the tree. |  |

| Step 11. Casting Product Finishing | |

| Burr free treatment, polishing and grinding. |  |

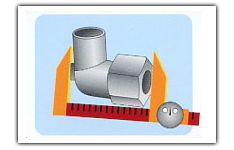

| Step 12. QC | |

| Every casting product is tested by various of test machines to ensure its quality. |  |

| Step 13. Delivery | |

| QC Passed -> Delivery |  |

- Movies