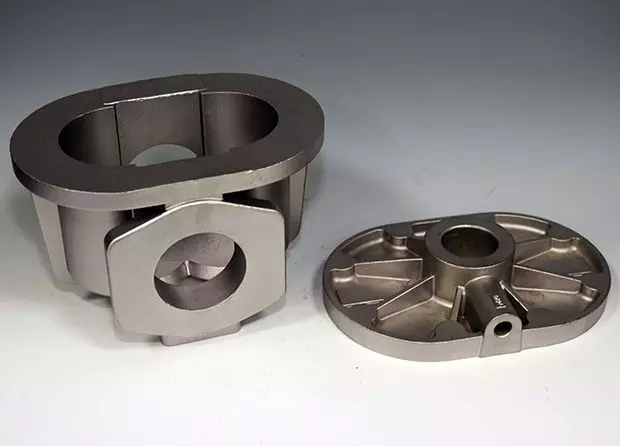

Hardware Part

002

Hardware Part

This product is very difficult for loatwax investment casting. The client has been tried this products for years, but the other foundry can not meet their quality requirement, no porodity either welding repair. One day, the R&D Manager asked LIN CHIAO if we can do this product. We did the sample test 2 times and ran the batch products in 40 days.

Material

Material AISI 304

Features

No porosity, No welding repair

Applications

- Explode environment

- Related Products

Hardware Part

001

This product is very difficult for loatwax investment casting. The client has been tried this...

Details

What safety certifications ensure these hardware parts perform reliably in explosive environments?

Beyond meeting industry standards, Lin Chiao's explosion-proof hardware components undergo rigorous testing for mechanical integrity, material composition verification, and pressure resistance. Our AISI 304 castings are specifically engineered to maintain structural integrity without porosity or welding repairs—critical factors in explosive environment certification. When procurement managers choose Lin Chiao, they receive comprehensive documentation validating that each component batch meets or exceeds the stringent requirements for hazardous environment applications, providing both regulatory compliance and operational peace of mind.

What sets this hardware part apart is our ability to overcome the significant casting challenges that had previously prevented reliable production. When approached by a client's R&D Manager after multiple failed attempts with other suppliers, Lin Chiao's engineering team completed successful sample testing within two iterations and moved to full batch production in just 40 days. The resulting AISI 304 stainless steel components feature exceptional metallurgical properties, consistent dimensional accuracy, and meet the stringent quality standards required for explosive environment applications where component failure is not an option.