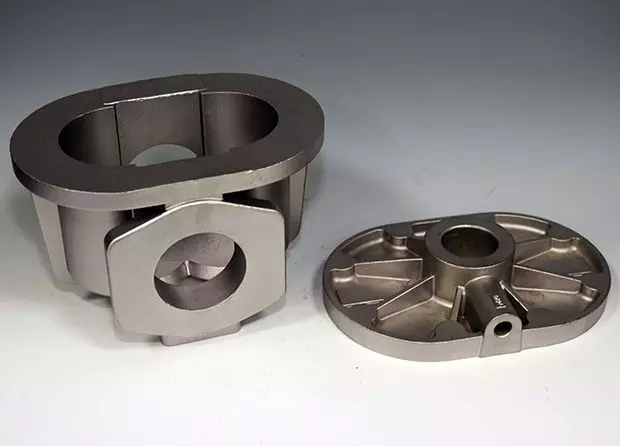

Hardware Part

001

Hardware Part

This product is very difficult for loatwax investment casting. The client has been tried this products for years, but the other foundry can not meet their quality requirement, no porodity either welding repair. One day, the R&D Manager asked LIN CHIAO if we can do this product. We did the sample test 2 times and ran the batch products in 40 days.

Material

Material AISI 304

Features

No porosity, No welding repair

Applications

- Explode environment

- Related Products

Hardware Part

002

This product is very difficult for loatwax investment casting. The client has been tried this...

Details

What Makes Lin Chiao's Investment Casting Process Superior for Explosion-Proof Hardware Components?

The difference lies in our specialized approach to investment casting developed over 35 years. While competitors struggled for years with this particular hardware component, Lin Chiao delivered perfect samples in just two test iterations and scaled to full production in 40 days. Our process ensures complete material integrity throughout the casting, eliminating porosity issues that plague conventional methods. For explosion-proof equipment suppliers, this translates to components that consistently meet the most stringent certification requirements without compromises or workarounds.

What sets our hardware parts apart is the exceptional manufacturing process developed through 35 years of investment casting experience. When a client approached us after years of unsuccessful attempts with other foundries, Lin Chiao's R&D team accepted the challenge and delivered superior results in just 40 days. The zero-defect manufacturing process we employ ensures these AISI 304 components maintain structural integrity throughout their operational lifetime, making them ideal for explosive environments where safety standards are paramount and component failure is not an option.