Customize Valve - Lost Wax Casting

001

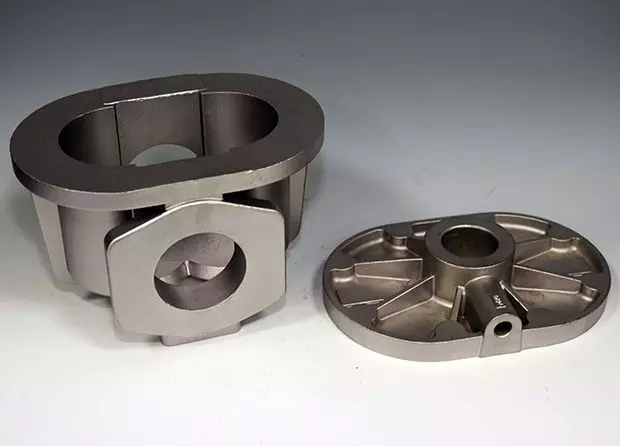

Twin valve

High quality customize valve parts (Precision Lost Wax Investment Casting) from Taiwan. We provided precision lost wax casting for customize valve parts with more than 24+ years OEM/ODM experience.

LIN CHIAO has been manufacturing stainless steel, carbon steel and other special Hastelloy C-22 products using investment casting process. Their one -stop investment casting service allowed them to supplier high standard casting products to the world.

LIN CHIAO has been cooperating with world leading companies for more than 10 years.

Some buyers request investment casting products with finishing processes. LIN CHIAO supplies reasonable investment casting prices with high standard csting process es.to win client's heart.

Material

1. AISI- 304, 304L, 316, 316L;

2. JIS- SUS304, SUS304L, SUS316, SUS316L;

3. DIN-17224/ 17440/17441- 1.4301, 1.4306, 1.4308, 1.4401,1.4408

4. ASTM-A351/ A743/A744- CF3M, CF3, CF8, CF8M

Features

1. Various design can be applied.

2. CNC Machining available.

3. Chemical test and tensile test available.

4. X-ray inspection available.

5. Stainless steel, carbon steel and special alloy available.

6. Ready to assemble.

7. Size from 1/8 ~ 6"

8. Weight from 0.1 kg ~ 50.0kg"

Applications

- Factory pipe installation

- Related Products

Customize Valve - Lost Wax Casting

002

High quality customize valve parts (Precision Lost Wax Investment Casting) from Taiwan. We provided...

Details

Tags

- investment casting products

- lost wax casting

- wax investment casting

- investment casting process

- wax casting

- steel investment castingStainless Steel Casting

- Stainless Steel Investment Castings

- lost wax investment casting

- investment casting

- Metal part casting

- Casting parts

- Investment Cast Component

- Component Casting

How Can Precision Lost Wax Casting Improve Your Valve's Performance and Durability?

Our investment casting process delivers valve components with superior metallurgical integrity and dimensional accuracy. By utilizing high-grade materials like 316L stainless steel and Hastelloy C-22, Lin Chiao produces valve parts with exceptional corrosion resistance and mechanical properties. This precision engineering translates to extended service life, improved flow characteristics, and reduced maintenance costs for your valve systems. Contact us to discover how our customized casting solutions can enhance your valve performance in demanding applications.

Each customize valve component undergoes comprehensive quality control, including chemical testing, tensile strength verification, and X-ray inspection to ensure compliance with international standards. Our one-stop manufacturing service covers the entire production process from casting to CNC machining, providing ready-to-assemble valve parts ranging from 1/8" to 6" in size and 0.1kg to 50kg in weight. Lin Chiao has established long-term partnerships with leading global valve manufacturers, delivering cost-effective solutions without compromising on quality or performance for factory pipe installations worldwide.