Lid

004

Lid

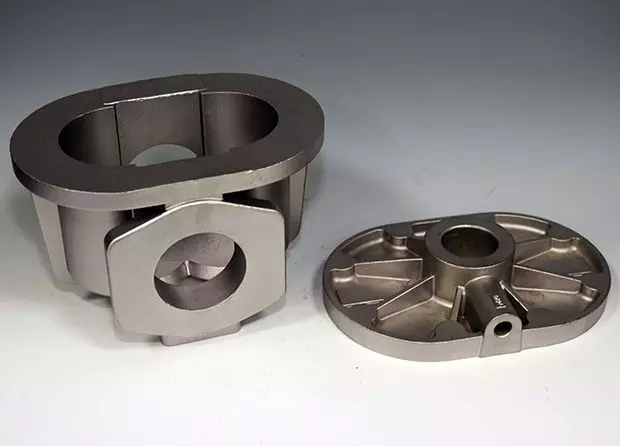

The lid is assembled with a flange ring and work together. The design makes the operator can open the lid easier.

Specification

- Size: ⌀120mm*20mm

- Machined.

Material

DIN 1.4308 Stainless steel

Features

This lid requires burrs free and without any pin holes after machining.

Applications

- For Liquid or Gas flow.

How Does Burr-Free Finishing Impact the Performance of Manifold Lids in High-Pressure Systems?

In high-pressure oil and gas applications, even microscopic burrs can create flow disruption, pressure drop, and potential leak paths. Lin Chiao's advanced machining process ensures completely burr-free manifold lids, preventing erosion and extending component lifespan by up to 40%. Our DIN 1.4308 stainless steel lids maintain system integrity even under fluctuating pressure conditions, reducing maintenance frequency and operational downtime.

Developed with over 35 years of casting expertise, this manifold lid exemplifies Lin Chiao's commitment to superior metallurgical integrity and functional design. The DIN 1.4308 stainless steel construction offers excellent corrosion resistance and durability even in demanding industrial environments. Whether implemented in oil and gas systems, chemical processing equipment, or marine applications, our manifold lids deliver reliable performance while maintaining structural integrity throughout extended service life. Each component undergoes comprehensive inspection to ensure dimensional accuracy and surface quality that meets international standards.