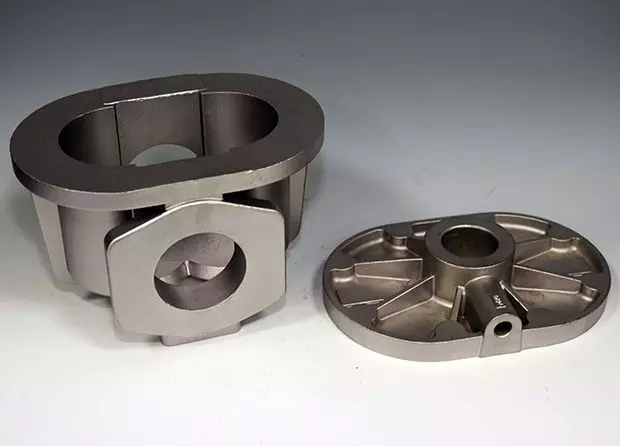

Joint - Lost Wax Casting

001

High quality joint parts (Precision Lost Wax Investment Casting) from Taiwan. We provided precision lost wax casting for joint parts with more than 24+ years OEM/ODM experience.

LIN CHIAO is expert in manufacturing pumps made from stainless steel, carbon steel and other special Alloy by investment casting process. The one -stop service including machining allowed us to provide high standard casting products to the world.

We have been cooperating with world leading companies for more than 10 years. The clients from Japan, UK, Germany, USA, Australia, Demark are satisfied with our products. The confidence from clients is our valuable treasure. As our clients design their products, they always welcome our advices to improve their design. The experience of co-operation leads us to move forward in the market.

It is not every founary owns a lot QC inspection facilities in house. But we has installed a lot of QC facilities to examine our casting technique. That is our promise to provide high quality products to our clients.

Material

17-4

Features

1. Various design can be applied.

2. Lost wax investment casting process.

3. CNC Machining available.

4. Chemical test and tensile test available.

5. Material 17-4 made.

6. Ready to assemble.

7. Weight from 0.06kg ~ 0.15kg.

Applications

- Hip Orthoses

- Related Products

Joint - Lost Wax Casting

002

High quality joint parts (Precision Lost Wax Investment Casting) from Taiwan. We provided precision...

DetailsJoint - Lost Wax Casting

003

High quality joint parts (Precision Lost Wax Investment Casting) from Taiwan. We provided precision...

Details

Tags

- investment casting products

- lost wax casting

- wax investment casting

- investment casting process

- wax casting

- steel investment casting

- Stainless Steel Casting

- Stainless Steel Investment Castings

- lost wax investment casting

- investment casting

- Metal part casting

- Casting parts

- Investment Cast Component

- Component Casting

How Can Precision-Cast Joint Components Improve Your Orthopedic Device Performance?

Our 17-4 stainless steel joint components offer the perfect balance of strength, weight, and biocompatibility for orthopedic applications. With weights ranging from 0.06kg to 0.15kg and ready-to-assemble precision, these components reduce device bulk while maintaining structural integrity. Our in-house CNC machining capabilities ensure tight tolerances and perfect fit integration, reducing your assembly time and improving patient comfort. Contact us to discuss how our joint components can enhance your orthopedic device performance.

Our comprehensive manufacturing capabilities include design consultation, precision casting, and CNC machining to ensure ready-to-assemble components that integrate seamlessly into your medical devices. Every joint part undergoes rigorous quality control testing, including chemical composition analysis and tensile strength verification, using our extensive in-house QC facilities. Our longstanding partnerships with leading medical device companies in Japan, UK, Germany, USA, Australia, and Denmark testify to our commitment to excellence in orthopedic component manufacturing.